Mail Us: info@mitmol.com Call Us:+91 9324294159

Screw Conveyors are simple, robust in design and maintenance friendly, they provide a low cost, versatile conveying capability with many bulk solids handling applications in manufacturing and processing units. They are available in wide range of options to suit various requirements.

Screw conveyor system is a mechanism that uses a rotating helical screw blade, called a "flighting", usually within a tube, to move liquid or granular materials.

They are mainly used in many bulk handling industries.

In modern industries, screw conveyors are often used horizontally or at a slight incline as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste, etc. and many others.

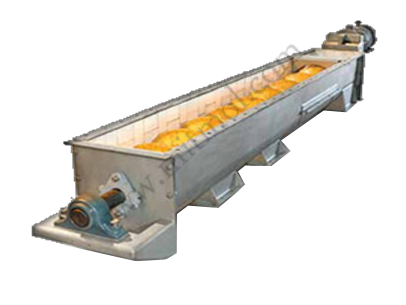

Such systems usually consist of a trough or tube containing either a spiral blade coiled around a shaft, driven at one end and held at the other, or a "shaftless spiral", driven at one end and free at the other. The rate of volume transfer is directly proportional to the rotation rate of the shaft.

In industrial control applications the device is often used as a variable rate feeder by varying the rotation rate of the shaft to deliver a measured rate or quantity of material into a process.

These systems can be operated with the flow of material inclined upward, and when space allows, these systems are very economical method of elevating and conveying.

The rotating part of the conveyor is sometimes called simply an auger.

These systems also find used use in snow blowers, to move snow towards an impeller, where it is thrown into the discharge chute. Combine harvesters use both enclosed and open augers to move the unthreshed crop into the threshing mechanism and to move the grain into and out of the machine's hopper.

They also find use in the much upcoming food processing industries. In a conventional meat grinder, chunks of meat are led by the auger through a spinning blade and a holed plate. This method emulsifies the fat in beef to soften hamburger patties, and is also used to produce a wide variety of sausages and loaves.

Another most important industry augers are used are in oil fields as a method of transporting rock cuttings away from the shakers to skips.