Mail Us: info@mitmol.com Call Us:+91 9324294159

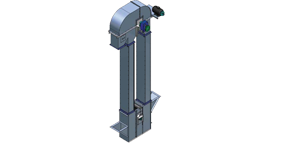

Bucket Elevators offer a practical, efficient and economical means of elevating a wide variety of dry and free flowing bulk materials. Typical elevators consist of a series of buckets mounted on chain or belt and enclosed in steel casings. Our Bucket Elevators are designed to cover practically every need in elevating loose bulk material. For every material there is a choice of one or more types and sizes which will serve your needs.

We manufacture the following types :A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials (most often grain or fertilizer) vertically.

Bucket elevators consist of:Accessories for loading the buckets or picking up the material, for receiving the discharged material, for maintaining the belt tension and for enclosing and protecting the elevator. A bucket elevator can elevate a variety of bulk materials from light to heavy and from fine to large lumps.

The centrifugal discharge elevator may be vertical or inclined depending on the use. Vertical elevators depend entirely on the action of centrifugal force to get the material into the discharge chute and must be run at speeds relatively high.

Inclined elevators with buckets spaced apart or set close together may have the discharge chute set partly under the head pulley. Since they don't depend entirely on the centrifugal force to put the material into the chute, the speed of such elevators may be relatively lower.

Most of the centrifugal discharge elevators have spaced buckets with rounded bottoms. They pick up their load from a boot, a pit, or a pile of material at the foot pulley.

The buckets can be also triangular in cross section and set close to on the belt with little or no clearance between them. This is a continuous bucket elevator. Its main use is to carry difficult materials at slow speed.

Bucket elevators come in different styles and most common of them seen in bulk material handling facilities are:

Centrifugal Discharge Elevators: Such styles of elevators are used in grain handling facilities we are all familiar with along rivers, ports or on the farm. The elevator buckets discharge product freely by the use of centrifugal force.

Positive Discharge Elevator: In these designs, buckets are used to elevate commodities such as popcorn, candy and potato chips where the utmost concern is on gentle handling and finished food grade applications. They require very careful handling so the products do not get destroyed. Such style elevator buckets operate off a double strand chain where they are held in place by two pins so the bucket is allowed to freely swivel.

Download Pdf