Roller Conveyor Systems

Tailoring systems to your material handling needs

Why Choose Our Roller Conveyor Systems?

Versatile for side loading, pushing off, and accumulating products.

Available in various types: chain-driven, belt-driven, line shaft-driven, and gravity conveyors.

Options include mild steel, galvanized, plastic, and stainless steel rollers.

Enhanced versatility with transfers, diverters, and stops.

Types of Roller Conveyors

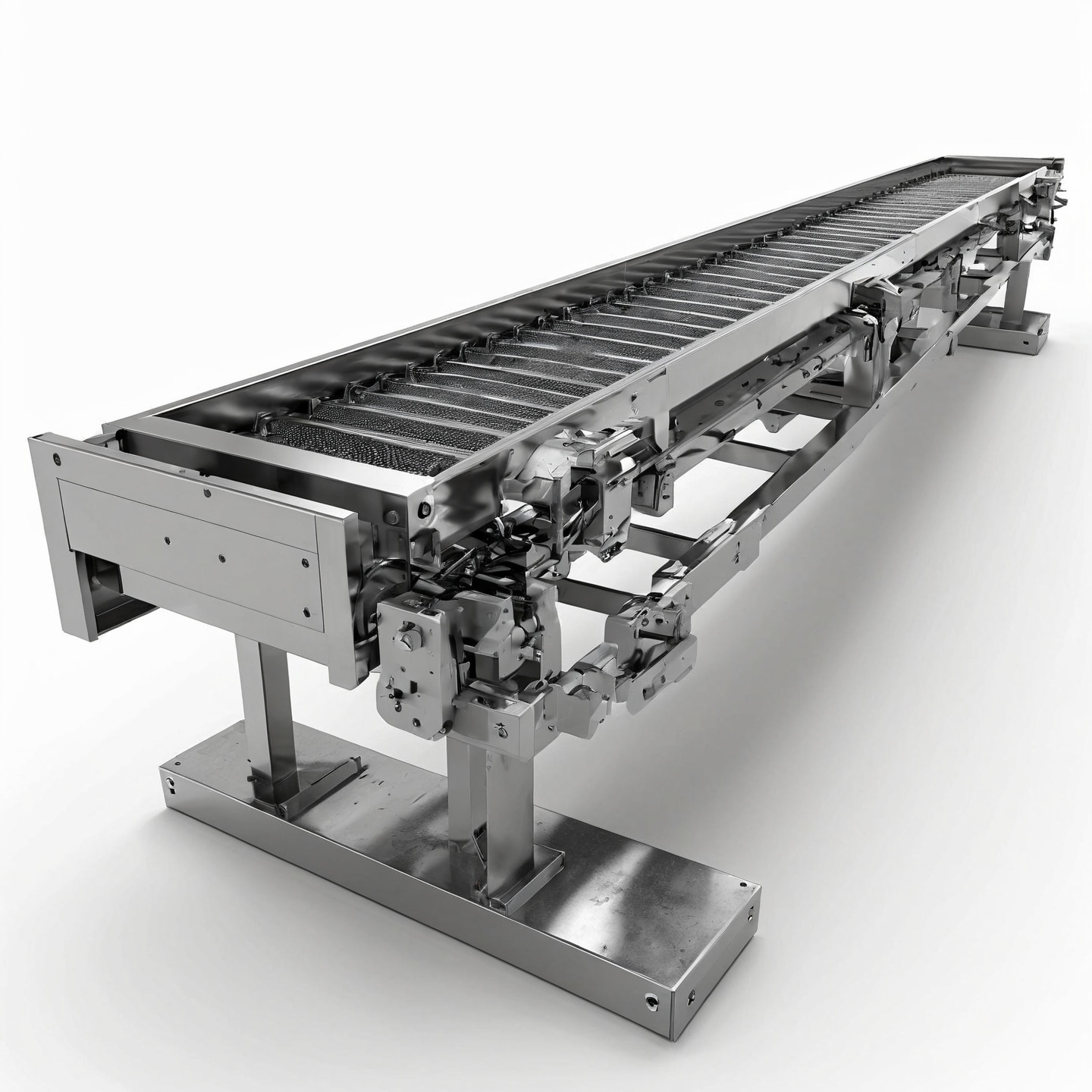

Chain Driven Powered Roller Conveyor Systems

Heavy-duty systems ideal for pallet handling, capable of handling loads from 1,500kg up to 7,000kg. Designed for robust industrial applications.

Belt Driven Powered Roller Conveyor Systems

Recommended for handling awkward or heavy items, such as bundled materials, drums, and pails. Useful for workflow interruptions where items must be removed from the line at specific points.

Gravity Roller Conveyor Systems

Ideal for economical, non-powered solutions where material flows through multiple conveyors into a single lane. Available in various roller materials for different applications.

Line Shaft Roller Conveyor Systems

Powered systems with minimal back pressure for smooth merges, low-pressure accumulation, and quiet operation. Easy to maintain and ideal for side loading.

Motorized Roller Conveyor Systems

Powered by motorized rollers, these systems are quieter and more efficient, eliminating the need for external drive units, chains, or shafts. Ideal for various industrial applications.

Industries We Serve

Manufacturing

Logistics and Warehousing

Recycling and Waste Management

Food and Beverage

Textile and Apparel

Automotive and Transportation

Ensuring Maximum Uptime

Our roller conveyor systems are engineered for durability and efficiency, ensuring continuous operation with minimal downtime. We implement best practices for maintenance and reliability:

Regular Inspections

Routine checks to ensure optimal performance and prevent potential issues.

Critical Component Monitoring

Constant monitoring of key components to avoid unexpected failures and ensure reliability.

Inventory Management

Maintaining a supply of essential parts to minimize downtime during repairs or maintenance.

Personnel Training

Comprehensive training for your team to ensure safe and efficient operation of the conveyor system.

Proactive Maintenance

Implementing proactive maintenance strategies to extend equipment lifespan and reduce long-term costs.

Advanced Diagnostics

Utilizing cutting-edge diagnostic tools to anticipate and prevent potential system failures.

Over 3 decades of expertise

Being in the business since 1990 has not only helped us carve out a niche in the highly competitive market but also maintain a steady edge over our competitors.