Bucket Elevators

Tailoring Systems to Your Needs

Why Choose Our Bucket Elevators?

Designed to handle a wide variety of bulk materials efficiently and economically.

Available in continuous, centrifugal, and positive discharge types to meet diverse needs.

Ideal for industries such as grain handling, food processing, and fertilizer manufacturing.

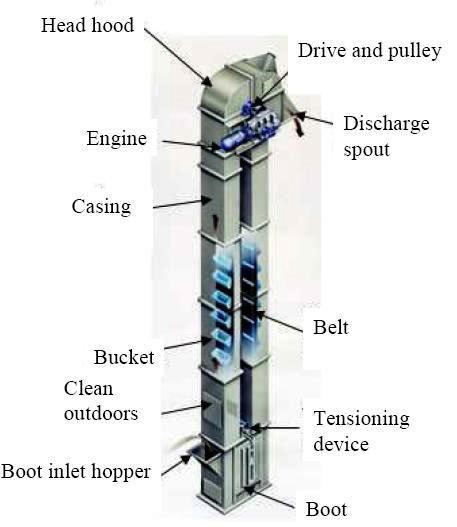

Features of Our Bucket Elevators

Perfect/Positive Chain Type

Centrifugal discharge elevators for free-flowing, fine or small lump materials such as grain, coal, sand, and dry chemicals. Buckets are mounted on a chain or belt, operating vertically or inclined.

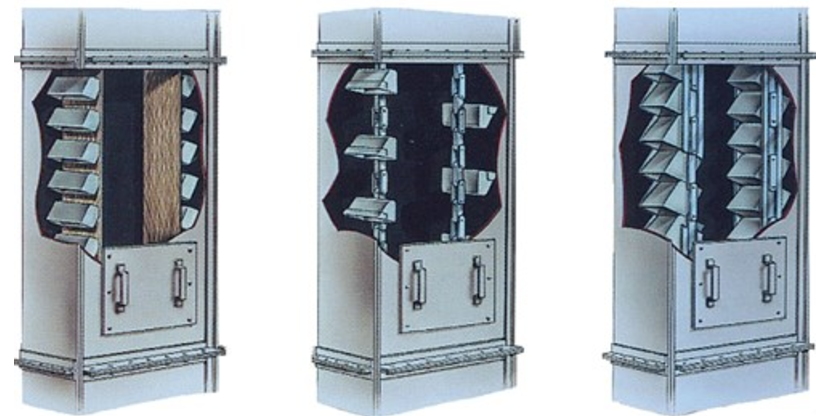

Continuous Discharge Chain/Belt Type

Recommended for heavy-duty, large capacity service. These elevators handle fragile materials, minimizing breakage with slow speed discharge and can be built in both vertical and inclined styles.

Centrifugal Discharge Chain/Belt Type

Designed to operate at higher speeds, this type is perfect for handling light, aerated, dusty, and sticky materials that won’t discharge cleanly from a centrifugal discharge elevator.

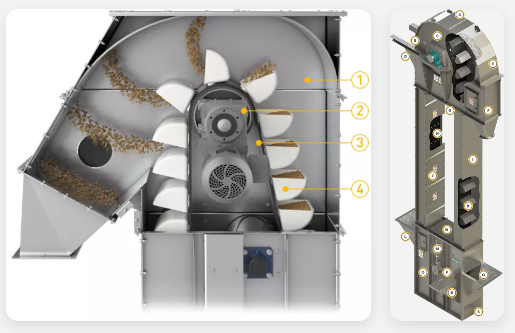

Super Capacity Continuous Elevators

These elevators are ideal for larger capacity materials such as coal, stone, and ore. The buckets are mounted between strands of roller chain and operate slowly for greater capacity.

Industries We Serve

Detergents & Chemicals

Food Processing

Packaging

Agriculture

Manufacturing

Recycling and Waste Management

Ensuring Maximum Uptime

Our bucket elevators are engineered for durability and efficiency. We implement best practices for maintenance and reliability:

Regular Inspections

Routine checks to ensure optimal performance and prevent potential issues.

Critical Component Monitoring

Constant monitoring of key components to avoid unexpected failures and ensure reliability.

Inventory Management

Maintaining a supply of essential parts to minimize downtime during repairs or maintenance.

Personnel Training

Comprehensive training for your team to ensure safe and efficient operation of the elevator system.

Over 3 Decades of Expertise

Since 1990, we’ve been a leader in the industry, carving a niche in the market with our innovative solutions and maintaining a steady edge over competitors.