Drag Conveyor Systems

Durable and Efficient Solutions for Bulk Material Handling

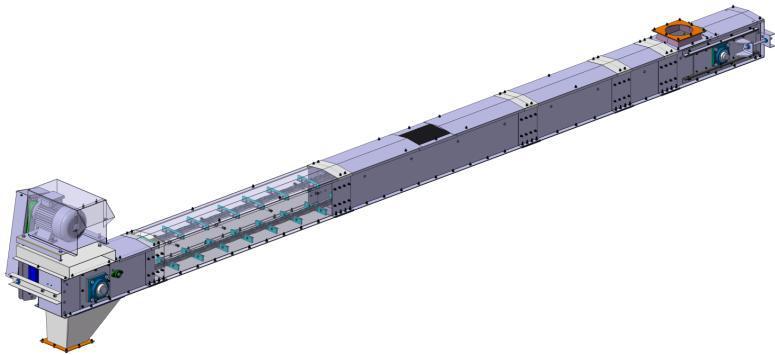

Flat Bottom Drag Conveyors

Perfectly crafted with a flat bottom design, this solution ensures smooth, efficient handling of bulk materials. Its optimized structure enhances material flow, boosting productivity and reducing operational disruptions.

Why Choose Our Drag Conveyor Systems?

Designed for long life and durability with minimum maintenance.

Fully enclosed, dust-tight, and quiet operation for gentle material movement.

Features extra heavy chain with UHMW polyethylene faced flights for reduced friction.

Suitable for abrasive materials like sand, coal, and cement, as well as sawdust and wood chips.

Industries We Serve

Construction

Mining

Sand Industries

Ensuring Maximum Uptime

Our drag conveyor systems are engineered for durability and efficiency, ensuring continuous operation with minimal downtime. We implement best practices for maintenance and reliability:

Regular Inspections

Routine checks to ensure optimal performance and prevent potential issues.

Critical Component Monitoring

Constant monitoring of key components to avoid unexpected failures and ensure reliability.

Inventory Management

Maintaining a supply of essential parts to minimize downtime during repairs or maintenance.

Personnel Training

Comprehensive training for your team to ensure safe and efficient operation of the conveyor system.

Proactive Maintenance

Implementing proactive maintenance strategies to extend equipment lifespan and reduce long-term costs.

Advanced Diagnostics

Utilizing cutting-edge diagnostic tools to anticipate and prevent potential system failures.

Over 3 decades of expertise

Being in the business since 1990 has not only helped us carve out a niche in the highly competitive market but also maintain a steady edge over our competitors.